Per la produzione delle visiere FK Visors abbiamo scelto di automatizzare solo parte dei processi produttivi, lasciando alle sapienti mani dei nostri artigiani alcune fasi importanti e delicate come la bisellatura ed altri importanti passaggi fino al controllo qualità che viene scrupolosamente eseguito su ogni singola visiera.

Questa attenzione ai particolari è il reale valore aggiunto che contraddistingue un prodotto FK.

Il reparto R&D FK VISORS testa e ricerca costantemente nuovi materiali per offrire ai propri clienti performance sempre più elevate.

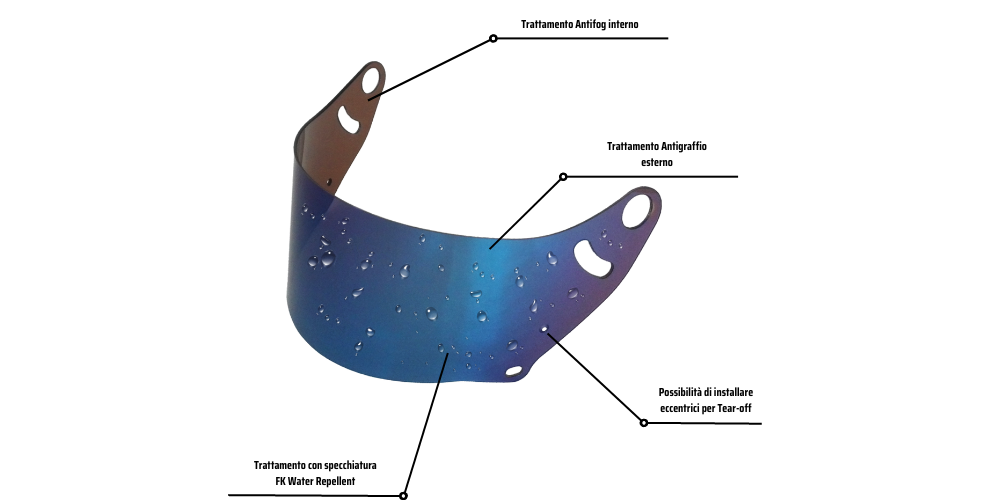

I materiali da noi utilizzati sono al 90% MADE IN JAPAN e i trattamenti antifog-antigraffio (coatings) sono inclusi nelle lastre.

- Lastre in policarbonato normali, senza trattamenti antigraffio-antifog

- Lastre in policarbonato con trattamento antigraffio da un lato o su due lati

- Lastre in policarbonato con trattamento antigraffio da un lato e antifog altro lato

- Lastre in materiale triacetato con trattamento fotocromatico e antifog

- Lastre in materiale triacetato con trattamento fotocromatico, polarizzante, antifog

- Spessori: 1mm, 1,5mm, 2mm, 3mm.

- Colorazioni di base: trasparente, fumè chiaro 50%, fumè bronzo 70%, fumè scuro 80%, arancio.

- Nello spessore 0,6mm con trattamento antifog nelle colorazioni trasparente, giallo, arancio

- Nello spessore 0,6mm con trattamento antifog e fotocromatico, nella colorazione trasparente

- Nello spessore 1,2mm con trattamento antifog e fotocromatico, nella colorazione trasparente e rosa

- Nello spessore 1,2mm con trattamento antifog e fotocromatico e polarizzante, nella colorazione trasparente

- In trasparente spessori 125 micron, 175 micron in policarbonato

- In trasparente spessore 130 micron, in poliestere crystal

- Nuovo materiale PLA o materiale eco-compatibile

- Laminatura kit di 5 tear-offs

Utilizzato il materiale acetato o triacetato da 0,6mm con sagoma adesiva 3M (perfetta aderenza e resistenza)

eccellenza artigiana

Ecco i processi che vengono eseguiti esclusivamente a mano dagli artigiani specializzati FK Visors

Sbavatura

Può essere eseguita sia manualmente che da robot antropomorfo a discrezione del reparto produzione. Le linee della visiera vengono bisellate questo rende i bordi più uniformi e lisci e quindi perfettamente compatibili con il casco di destinazione.

svasatura

I fori presenti nella visiera vengono alesati e svasati al fine di ottenere rotazioni ottimali per favorire un montaggio di precisione sul casco di destinazione.

Controllo qualità

Il controllo qualità finale prevede che ogni visiera sia priva di graffi, imperfezioni e idonea al confezionamento.