tailored to realize your ideas

We work in visors sector from over 30 years, we know that precision and details attention are fondamental. Over the years the internal processes are changed and renewed, thank to the purchasing of new technologies. Thanks to this investments, today, we can offer to customer processes that not concerned with visor production, but relating to plastic materials.

Do you want to realize a new product/project, but you don't know how to make it?

Our technicians can support you in each phase and will guide you step by step to make your idea concrete.

Contact us to have more information or to request an advice.

Each request must be subject to a feasibility assessment and dedicated estimate.

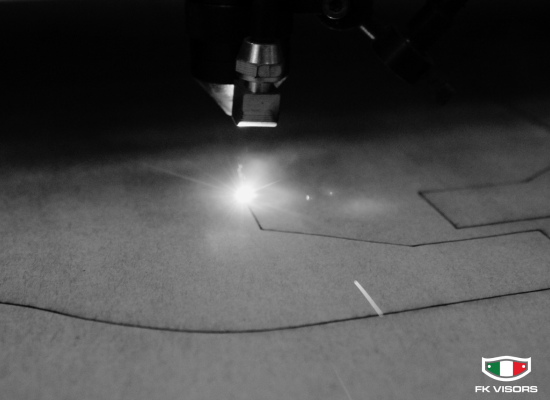

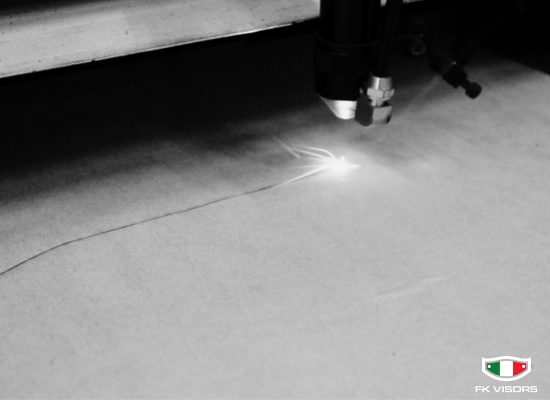

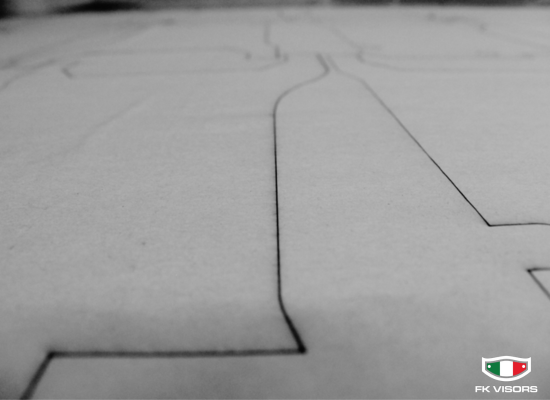

The Laser cutting is a thermic separation process that through the vaporization or fusion of material give the opportunity to make precise cut.

The Kerf, that could change based on cutted material, is bigger than laser dimension. This cutting method offer the opportunity to avoid other processes to make better the final output, like deburring or countersunking.

The cut it's possible thanks to a infrared light beam which is powered by the gas contained in the tube.

This gas is composed by Carbon Dioxide (CO2), Nitrogen (N2), Hydrogen (H2) or Xenon (Xe) and Elio (He), the mixture of components varies based on the final use and the type of operation to be carried out, cutting or engraving.

Thanks to this cutting method, the effects due to tool advancement forces are avoided, such as the movement of the material during processing or the wear of the cutting tool.

Thnsk to specific drivers the software can perfectly replicate the desired shape.

The vector file, from which the design phase begins, can be easily modified and can be adapted to customer need.

Below we make a list that include some advantages that can be obtained with laser cutting

This process is perfect to cut soft material.

Our CNC machines, that are used for this process, offer the opportunity to make extremely precise and repeatable cut , is possible to make cutting on materials that are extremely thin or extremely flexible. The materials range from polycarbonate, to cardboard, fabrics and plastic materials of all types.

Advantages

Suitable for very small thicknesses

For textile industry

Extremely precise

Speed

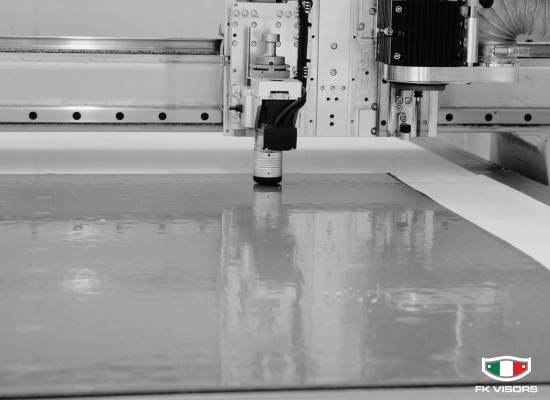

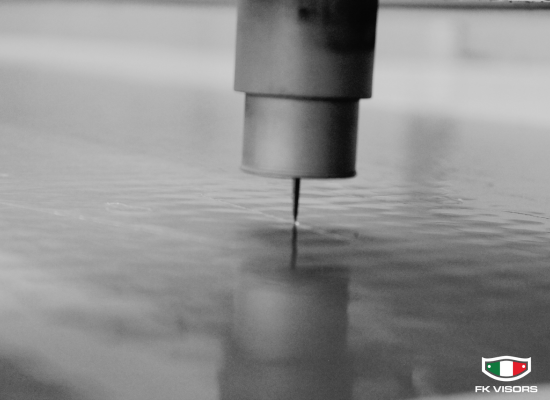

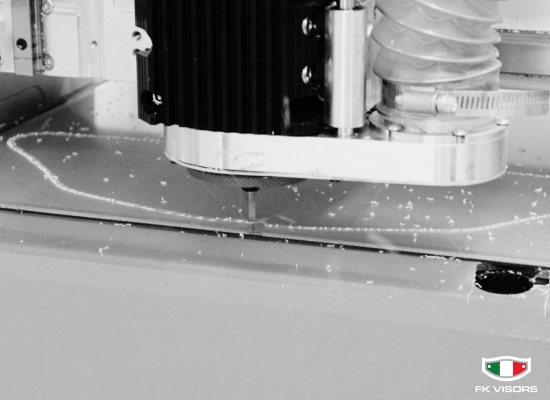

Our CNC pantograph milling machines are projected to work polycarbonate sheetsthat have high thicknesses.

Compared to other types of milling machines, the main characteristics for our production are the execution speed, spindle rotation speed that could can reach 50,000 RPM, and the almost total absence of vibrations, a fundamental aspect for obtaining sectional cuts without steps and chipping.

The working phases realized with mill that have small diameter allow to make precise cut, like lateral serrations of the visor kinematics.

Our die cutting process is made by 35 TON die-cutting press, through the use of forged or electroerosion steel dies.

Is the method that we use since our begin, this technique allow to obtain high quality cut on shape precision..

Despite we use this technique from the begin of '80s, is still today the ideal solution for determinate productions, for example the tear-offs production that are utilized on some motorsport helmets.

Advantages

Precise cut

Suitable for few pieces

Execution speed

Minimum costs, after the cost of the die is amortized

We have also the numeric control pad printing.

The pad printing is based on trasfering of ink from an engraved slab, or cliché, to another surface through a siliconic pad.

The pad is the main element of this type of printing, due to its shape and specific hardness, its adapt perfectly to the figure of objects, replicating excellent quality prints even on small pieces.

Another important element is the used ink, that can be different from colors and composition,

in fact today it is possible to print on each material. The effect of evaporation of solvents contained in the ink causes the design to be imprinted on the object concerned.

The pad printing process lasts few seconds, the phases are as follow:

- Stall: In stall position, the pad is over the product to be marked and the inkwell, that contain ink, is over the engraving.

- Start In this phase the pad or cliché, depend on type of machine possessed, move to allow to the pad to "catch" the ink that is in the engraving;

- Positioning The pad stay on object to be marked, into this phase thanks to the solvents evaporation, the ink acquire the ideal viscosity;

- Marking: The pad go incontact with the surface and releases the ink.

Advantages

Suitable for few pieces

High personalization

High precision also for small details

Durable and resistant prints

Speed

We have a new compact laser marking, that guarantee high precision and repeatability standard of marking

The laser marking is used to make logos, add dates, serial numbers and other products information.

This marking process, define contactless marking, allow to permanently marking the objects, for this reason it used for:

Aestethics objects and products personalization throught the brand application

Traceability: the permanent marking allows to univocally trace the product supply chain.

The light beam is previously calibrated to release the right power, heat up the product until the surface aspect modification, in this way the beam can replicate the traceability information or to make the desired design.

Being a contactless technology, the laser marking allows engraving of products and identification,

Laser marking is studied to guarantee durability over time and resistance to corrosion from atmospheric agents and acids. Another advantage is the speed and versatility of this technology. The marking laser machine, based on the source used (Co2 or fiber), can be used on different material increasing productivity and particularly convenient.

Advantages

Suitable for few pieces

High precision also for small details

High personalization

Durable and resistant prints

Speed

Is our maincompany process, the one that give shape, roundness and radius to our visors.

On a technical level the word "thermoforming" isn't right beacuse to preserve the visors optical purity the material is never softened.

Advantages

Suitable for few pieces

High precision also for small details

High personalization

Have you got a project?

Let talk to us

*Required field